What Are the Differences Between Studs and Bolts?

When it comes to assembling engines, the debate between head studs vs. bolts is a pivotal consideration that can significantly impact performance and reliability. Let’s delve into the specifics of these fastening components and understand the key differences that set them apart.

Head Studs: Stability and Precision

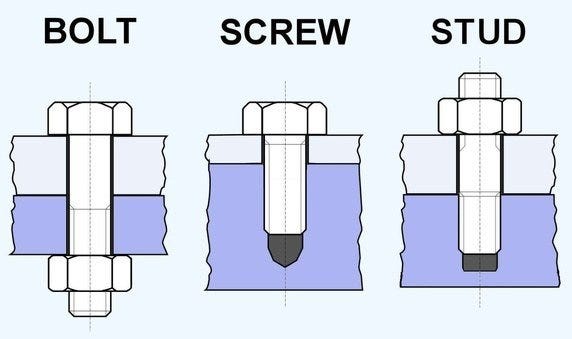

Head studs are threaded rods that play a fundamental role in securing the cylinder head to the engine block. What sets head studs apart is their unique design — they extend from the block’s deck surface, avoiding direct threading into the block. This design choice provides a more even distribution of load, minimizing the risk of thread damage in the block.

The standout advantage of head studs lies in their ability to deliver consistent clamping force. This stability is crucial for maintaining cylinder head alignment, especially in demanding applications like racing or high-performance engines. Head studs shine in scenarios where stability under extreme conditions is paramount.

Bolts: Conventional Simplicity

Bolts, the traditional fastening solution, thread directly into the engine block. While bolts are widely used and familiar, they come with considerations. Their threading into the block may pose challenges under heavy loads, leading to uneven torque distribution or potential thread damage during installation.

Bolts are favored for their simplicity and ease of installation, making them a practical choice for less demanding applications or scenarios requiring frequent disassembly. However, it’s essential to note that the overall stability and load distribution may not be as consistent as with head studs.

Choosing the Right Component

The decision between head studs vs. bolts hinges on specific engine requirements, the intended use, and the desired level of performance. In applications demanding precision torque control and stability, such as high-performance or racing engines, head studs are often the preferred choice. Bolts, on the other hand, may suffice for standard applications, offering a simpler and cost-effective solution.

In conclusion, the choice between head studs vs. bolts is a critical decision that necessitates a careful assessment of the engine’s demands. Whether aiming for optimal performance on the track or reliable daily driving, understanding the nuanced differences between head studs and bolts is essential for ensuring the longevity and efficiency of the engine.

What are head studs on a diesel?

Head studs on a diesel engine are threaded rods that play a crucial role in securing the cylinder head to the engine block. Unlike bolts, head studs extend from the block’s deck surface, providing a more even distribution of load and enhancing stability. They are a key component in high-performance and heavy-duty diesel engines, ensuring a secure and reliable connection between the cylinder head and the engine block.